Leave Your Message

The automobile industry is undergoing a transformative shift as innovative drive technologies emerge, fundamentally altering not only vehicle performance but also the global supply chains that support them. According to a report by McKinsey, the market for electric vehicles (EVs) is projected to grow to $1.7 trillion by 2030, driven largely by advancements in automobile drive systems. This shift is creating a cascading effect on supply chains, necessitating agile responses to new demand patterns and the sourcing of raw materials for batteries and other components. Furthermore, the World Economic Forum highlights that smart mobility solutions, including connected and autonomous vehicles, are expected to contribute up to $2 trillion to the global economy by 2030, reshaping logistics and manufacturing processes. As automobile drive innovations accelerate, understanding the top strategies that will navigate these changes is essential for stakeholders aiming to thrive in an increasingly competitive landscape.

As we look toward the future of vehicle automation, the integration of advanced technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) holds immense transformative potential. These innovations are not merely enhancements to existing vehicle capabilities; they fundamentally redefine how vehicles operate and interact with their environments. Autonomous driving systems are expected to improve safety by reducing human error, which accounts for a significant portion of traffic accidents worldwide. Furthermore, advancements in sensor technology and real-time data processing will enable vehicles to communicate with each other and infrastructure, paving the way for more efficient traffic management and reduced congestion.

The implications of these developments resonate far beyond the automotive industry. Vehicle automation will likely reshape global supply chains, enhancing logistics and distribution networks. For example, self-driving trucks can operate around the clock, minimizing delivery times and optimizing routes through real-time traffic analysis. This efficiency not only reduces operational costs for companies but also caters to the growing consumer demand for faster service. Additionally, as more businesses embrace electric and automated vehicles, there will be shifts within the supply chain, necessitating new partnerships and collaborations among stakeholders. The evolution of vehicle automation is set to transform not just our roads and cities, but the very framework of global commerce.

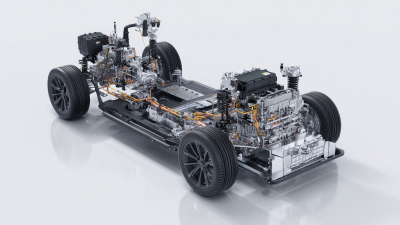

The rise of electric vehicles (EVs) is reshaping supply chain dynamics in the automotive industry. As manufacturers pivot towards sustainable technologies, they are revolutionizing not just how vehicles are produced, but also how components are sourced and supplied. Traditional supply chains, heavily reliant on fossil fuels and non-renewable resources, must now adapt to incorporate a myriad of new materials essential for EV production, such as lithium for batteries and rare earth metals for electric motors. This shift necessitates a reevaluation of sourcing strategies and partnerships, emphasizing the importance of sustainable, ethical sourcing practices to meet both regulatory standards and consumer expectations.

Moreover, the electrification of vehicles has prompted a regionalization of supply chains. As the demand for EVs accelerates, automotive companies are increasingly looking to localize production to reduce transit times and costs, while simultaneously minimizing their carbon footprints. This transition is fostering closer collaboration among suppliers, manufacturers, and logistics providers, creating a more interconnected ecosystem. The implications of these changes extend beyond the automotive sector, influencing industries involved in battery production and recycling, energy supply, and even infrastructure development, paving the way for an integrated approach to sustainability and innovation in global supply chains.

| Innovation | Impact on Supply Chain | Challenges | Opportunities |

|---|---|---|---|

| Electric Vehicles (EVs) | Shifts in raw material sourcing, increased demand for charging infrastructure | Limited battery material suppliers, recycling logistics | New markets for battery recycling, investment in renewable energy |

| Autonomous Driving Technology | Changes in vehicle utilization and ownership models, new transportation businesses | Regulatory hurdles, technology standardization | Development of smart cities and improved logistics efficiency |

| Connected Vehicles | Integration with IoT for real-time data usage in logistics | Data privacy issues, cybersecurity risks | Enhanced fleet management, predictive maintenance opportunities |

| Shared Mobility Services | Reduced need for vehicle ownership, shift in logistics demand | Market acceptance, competition from traditional models | Increased partnership opportunities with local businesses |

The automotive manufacturing sector is undergoing a transformative phase driven by the integration of artificial intelligence (AI) and robotics. By 2034, the automotive robotics market is projected to witness significant growth, fueled by the increasing need for enhanced production efficiency and cost optimization. As manufacturers strive to streamline assembly lines, robots have become indispensable assets in achieving these goals. Reports indicate a robust compound annual growth rate, demonstrating the industry's commitment to automation in the face of labor shortages and ongoing supply chain disruptions.

Furthermore, AI's role in supply chain management cannot be underestimated. The rise in complexity and unpredictability within global logistics has emphasized the need for advanced technological solutions. Research forecasts that the AI packaging market is expected to reach a valuation of $2.4 billion by 2024, with a compound annual growth rate exceeding 10.1% from 2025 to 2034. This growth is largely attributed to the demand for greater supply chain transparency and traceability, which AI technologies adeptly provide. As manufacturers leverage these tools, the landscape of automotive production is set to evolve, reshaping operations for improved resilience and responsiveness.

This chart illustrates the projected market growth of various automobile drive innovations, including Electric, Hybrid, Autonomous, and Connected Vehicles, emphasizing their potential impact on global supply chains in the automotive sector.

Sustainability is becoming a cornerstone in the automotive industry, driving innovation and reshaping supply chains across the globe. As manufacturers pivot towards eco-friendly materials and electric vehicles, their supply chains must adapt to accommodate these new technologies. For instance, the shift to electric vehicles necessitates sourcing rare materials like lithium for batteries, prompting automakers to re-evaluate their procurement strategies and relationships with suppliers. This change encourages a more circular economy, where recycling and sustainable practices play a significant role in reducing waste and emissions.

Moreover, advancements in automotive technology are intertwining with sustainability goals, leading companies to invest in green manufacturing processes. By implementing energy-efficient production methods and reducing carbon footprints, automakers can enhance their brand reputation and appeal to a more environmentally conscious consumer base. The integration of artificial intelligence and IoT in supply chain management further optimizes logistics, minimizes resource consumption, and ensures more transparent tracking of materials, thus enhancing overall sustainability. As these trends continue to evolve, the future of automotive innovations will be significantly influenced by their ability to align with sustainability objectives, ensuring a more efficient and responsible global supply chain.

As the automotive industry braces for groundbreaking innovations in vehicle drive technologies, global collaboration will become pivotal in navigating the accompanying challenges in supply chains. The emergence of electric vehicles and autonomous driving systems necessitates a reevaluation of traditional supply chain models. Automakers and suppliers must work together across borders to establish reliable networks that facilitate the rapid production and distribution of new components, like batteries and advanced sensors, which require specialized materials often sourced from various countries.

However, collaboration in the automobile sector is fraught with complexities. Geopolitical tensions, trade policies, and varying regulatory standards can disrupt the smooth flow of goods and information. To mitigate these risks, stakeholders must prioritize transparency and foster strong partnerships. Utilizing digital technologies like blockchain can enhance traceability and trust along the supply chain, enabling participants to respond swiftly to uncertainties. Ultimately, the future of automobile innovations relies not just on technological advancements but also on the cooperative spirit that can drive a more resilient global supply chain.